Precision Spindle Repair

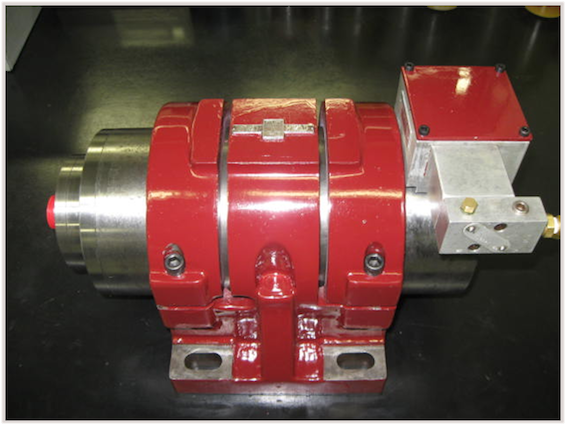

McBroom specializes in the rebuild of all types of spindles, equal to or better than the manufacturer’s specifications.

- In-depth inspection and analysis

- Written repair quotation

- Obsolete part manufacturing

- Precision surface regrinding

- Stator rewinding

- Worn component replacement

- Precision balancing

- We will arrange to have your spindle delivered to our facility where it will be disassembled, inspected and evaluated. After evaluation a detailed quote will be sent to you for your approval.

- All parts will be meticulously examined for proper fit and geometry using the latest measuring equipment All critical dimensions are returned to print specifications or better to ensure trouble-free operation.

- Every spindle shaft is dynamically balanced with computerized equipment to some of the tightest tolerances in the industry.

- McBroom will work with your manufacturing engineers to make spindle modifications such as special sleeving, stator insulation, modifications to accept sealed bearings, slingers or special oiling requirements.

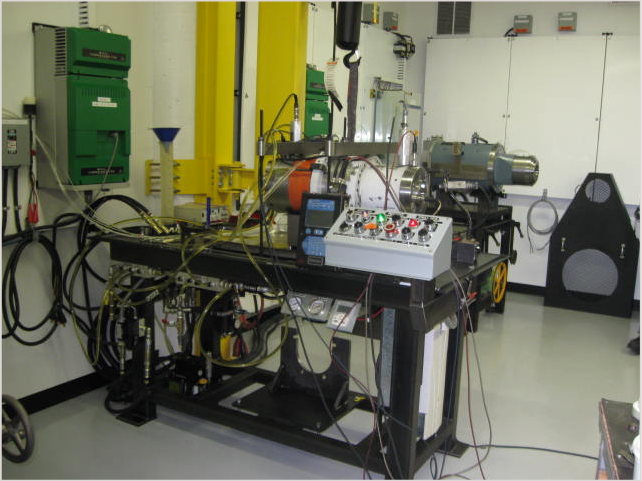

- Our fully-equipped spindle repair facility specializes in the repair of precision, high speed, high frequency and belt driven spindles, servicing the automotive, machine tool and aerospace industries.

- McBroom can improve your capabilities and productivity and lower your maintenance costs. Our skilled technicians will provide quality repairs promptly and accurately with complete diagnostic documentation.

Why use McBroom for your spindle repairs?

- Increased machine uptime

- Greatly reduced turnaround time

- Design enhancements decrease your repair costs